|

Cold-Flow Corporation Burr Ridge, IL 60527 - Phone:(630)325-1091 - Fax:(630)325-8652 |

|---|

Printer-Friendly

Printer-Friendly  Email Page

Email Page

Improved material usage, reduced forging energy, and the elimination of machining processes with high precision forging are just a few reasons to consider cold forging as an alternative to other methods of manufacture. The current energy crisis, material shortages, and rising costs have combined to force consideration of greater efficiency in parts making. The advantages of cold formed parts can reduce the effect these issues have on the production process.

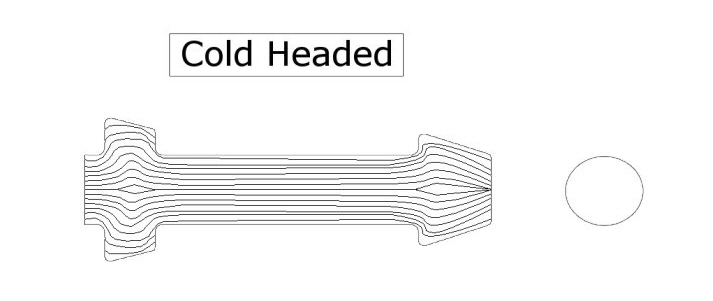

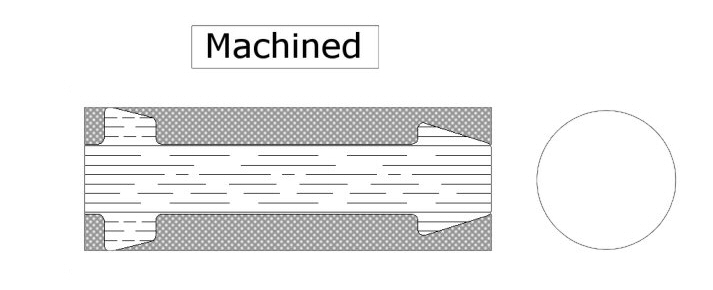

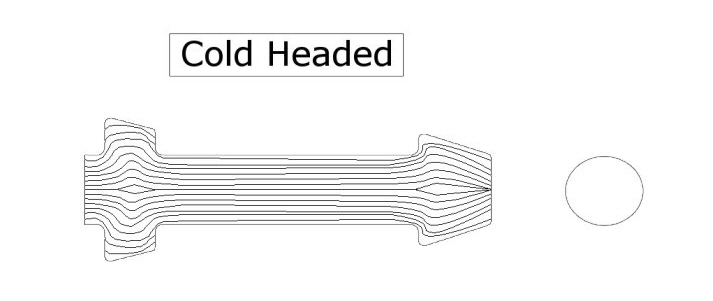

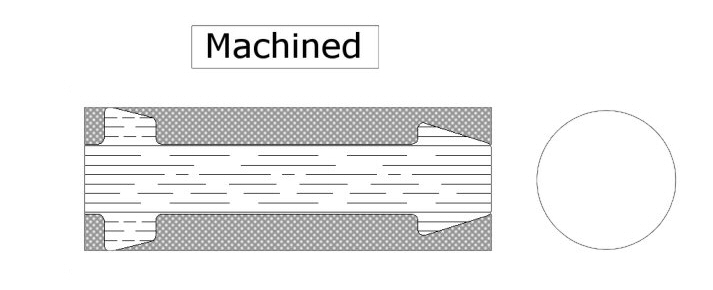

Material savings is evident in the image of the shaft (below). The shaft on the right is machined out of bar stock and results in approximately 64% loss of material. The shaft on the left is formed and extruded to form a head and nose. In addition to the saviungs because the material required to make the cold formed part is approximately 40 percent less. Cold forming the shaft produces a part with a far superior grain structure as shown by the lines below.

Home | About Us | Cold Forging | Warm Forging|

| Contact Us |