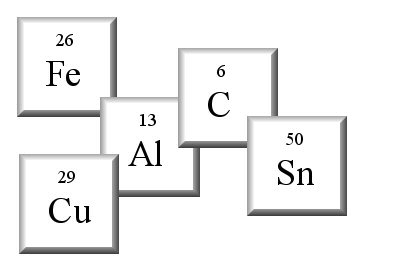

CARBON STEEL ALLOY STEEL COPPER BRASS/BRONZE ALUMINUM

|

Grade

|

Description

|

Forging Characteristics |

|

1008

|

Ball Joint Housings, Bushings, Ball Studs, Ordnance Items,Thrust Ring, Universal Joints, Wheel Nuts Axle shafts, Bolts, Ball Joint Studs, suspension struts, Generator shafts, engine mounts, idler arm, mining equipment, mortar shells, motor shafts, oil field equipment, propeller shafts, sockets, wrenches, truck axels, tortion bars, yolkes |

Excellent

|

|

1010

|

Excellent

|

|

|

1018

|

Excellent

|

|

|

1045

|

Good-Fair

|

|

|

1050

|

Fair-Poor

|

| Grade |

Uses

|

Forging Characteristics

|

|

4037

|

Bushings, Bolts, Ball studs, Bearing Races, nuts, ordinanace items, Piston Pins, pistons, pinions, rollers, starter drive parts, Steering worms, sun gears, shafts, |

Good-Fair

|

|

4130

|

Fair-Poor

|

|

|

4140

|

Fair-Poor

|

|

|

4142

|

Fair-Poor

|

|

|

4150

|

Fair-Poor

|

|

|

4340

|

Fair-Poor

|

|

|

52100

|

Not recommended

|

|

|

8620

|

Good-Fair

|

|

Grade

|

Description

|

Forging Characteristics |

|

101, 102, 103, 104, 105, 107

|

Oxygen Free

|

Excellent |

|

110, 113, 114, 115, 116

|

Tough Pitch

|

Excellent |

|

122, 145

|

Phosphorus Deoxidized

|

Excellent-Good |

|

125, 127, 128, 129, 130

|

Free Refined Tough Pitch With Silver

|

Excellent |

|

143

|

Cadmium Copper

|

Excellent |

|

147

|

Sulfur Bearing

|

Excellent-Good |

|

150

|

Zirconium Copper

|

Excellent |

|

162

|

Cadmium Copper

|

Excellent-Good |

|

170, 172, 173

|

Beryllium Copper

|

Excellent-Good |

|

175, 182, 184, 185

|

Chromium Copper

|

Excellent-Good |

|

187, 189, 190, 191, 192, 194, 195

|

Leaded Copper

|

Excellent-Poor |

|

Grade

|

Description

|

Forging Characteristics |

|

220

|

Commercial Bronze, 90%

|

Excellent-Good |

|

260

|

Cartridge Brass, 70%

|

Excellent-Fair |

|

268, 270

|

Yellow Brass

|

Excellent-Poor |

|

280

|

Muntz Metal, 60%

|

Excellent-Fair |

|

314, 316

|

Leaded Commercial Bronze

|

Good-Poor |

|

330, 353

|

Leaded Brass

|

Excellent-Poor |

|

360

|

Free Cutting Brass

|

Fair-Poor |

|

464

|

Naval Brass

|

Excellent-Poor |

|

510, 544

|

Phosphor Bronze

|

Excellent-Poor |

|

624, 630, 642

|

Aluminum Bronze

|

Excellent-Poor |

| Grade |

Uses

|

Forging Characteristics

|

| 1100 |

HeatExchangers, Marine Applications, Rivets, Gears, Overhead Cranes, Pipe Fittings, Buss Conductors, Aircraft Parts, Vavle Bodies, Impellers, Refrigerator Fittings, Food Handling Equipment, Carburetor Bodies, Air Compressor Pistons, Heatsinks, Aircraft Engine Crank Cases, Automotive Parts, Trowel Handles, Pipe Flanges, Water Heater Parts, Forged Pistons, Aircraft Engine Cylinder Heads and Pistons, Aircraft Structure, Landing Gear, Wheel Hubs, Ordinance, Missle Parts |

excellent

|

| 2011 |

fair

|

|

| 2024 |

fair

|

|

| 3003 |

excellent

|

|

| 4032 |

difficult

|

|

| 5055 |

excellent

|

|

| 5052 |

excellent

|

|

| 6061 |

excellent

|

|

| 6066 |

good

|

|

| 7075 |

difficult

|

Phone:630-325-1091 Fax:630-325-8652

Phone:630-325-1091 Fax:630-325-8652  Printer-Friendly

Printer-Friendly