Methods of Cold Forging

The methods of cold forming most commonly used are forward and backward extrusion. Both require a combination of properties to meet extrusion requirements. Material properties are one of the most important properties to be considered when deciding to use a cold extrusion process. In addition to extrusion, there are many other methods which can be used by themselves or in conjunction to achieve a part made solely by cold forming.

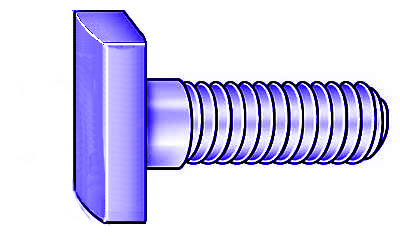

A T-headed bolt, for example, could be made using a technique called upsetting. In this method a round billet would be placed inside a die and a punch would impact the top of the piece causing the material to flow in multiple directions until the cavity filled completely. The stem could then be machined and threaded to complete the part. Alternately, if the billet was pre-formed using a forward extrusion process, the stem could be made to the pitch diameter of a thread. A subsequent roll threading process would complete the part and no additional machining would be necessary. Combining cold forming techniques can provide an overall savings above and beyond the method originally used.

Other methods of cold forming are coining, ironing, punching, piercing, blanking, and trimming. Combining a cold forging operation with coining or ironing can produce a part with extremely tight tolerances. A cold forging can generally achieve tolerance of + or - .005". Coining a cold forged part can produce parts as precise as + or - .002" on some dimensions. Punching or piercing can be used to make holes. Punching a hole can be done when the material is no thicker than the diameter of the hole. This technique does not create features as precise as drilling but it is very quick and therefore, very cost effective. Blanking (also called stamping) and trimming can be used to create a profile shape. In blanking, flat material is used and the shape is cut somewhat like a cookie cutter. Trimming is used when a forming operation leaves material in the form of flash around the edges of the part. As with punching, blanking and trimming do not create features as precise as machining but the speed at which it can be done makes it very attractive when large quantities are involved.

Phone:630-325-1091 Fax:630-325-8652

Phone:630-325-1091 Fax:630-325-8652  Printer-Friendly

Printer-Friendly