History of Forging

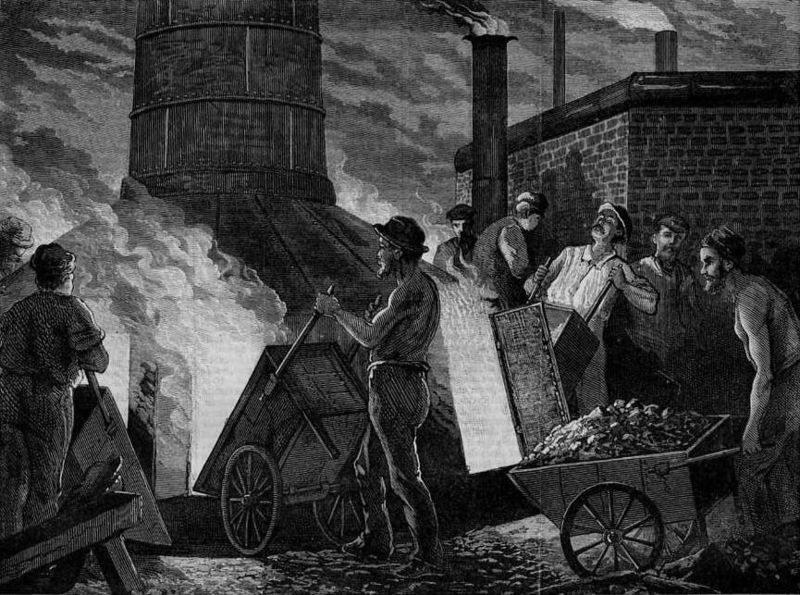

Forging dates back to the days when prehistoric people learned to heat sponge iron and beat it with a stone to form a useful implement. It is the oldest known metal working process from which the ancient art practiced by the armor makers and the immortalized village blacksmith developed into the Modern forging we know today. As new metals were discovered so were the methods needed to refine and shape them. Stone age man learned to fashion gold into jewelry and ornaments, but its ease of forming ensured that it would have no utilitarian value. The first tools, implements, and weapons were made from copper between 6,000 to 4,000 BC. Smelted copper was rarely pure, in fact, it is clear that by 2500 BC the Sumerians had recognized that if different ores were blended together in the smelting process, a different type of copper, which flowed more easily, was stronger after forming, and was easy to cast, called Bronze could be made. Iron was available in small amounts from meteors. Iron making did not become an everyday process until 1200 BC. Iron weapons revolutionized warfare and iron implements did the same for farming. Iron and steel were the building blocks for civilization

Mechanical and hydraulic presses now replace the strong arm tools of the blacksmith, and modern metallurgy has improved the process and capabilities. Higher strength, integrity, more consistency, and higher metallurgical properties provide the forging process a considerable advantage over other manufacturing processes. In 1995, there were approximately 450 facilities at which the forging process was performed in the United States according to trade press estimates. Forging plants are primarily small or medium-sized companies that employ fewer than 250 employees. Primarily plants that forge parts are independent custom-forged part producers, original equipment manufacturers, government research laboratories, and military arsenals.

Phone:630-325-1091 Fax:630-325-8652

Phone:630-325-1091 Fax:630-325-8652  Printer-Friendly

Printer-Friendly